We provide wide range of product development support to the automotive industry at all stages of the design and development cycle from concept to field failures.

We have focused and knowledgeable teams in both CAD and CAE working together for various Automotive domains and having excellence in their domain and well versed with leading software tools required.

- Body Development & Full Vehicle Integration

- Interiors & Seating System Development

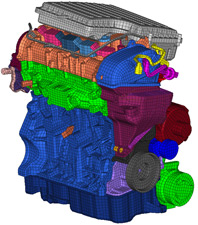

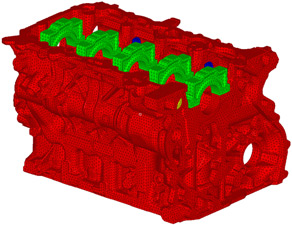

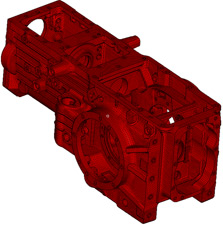

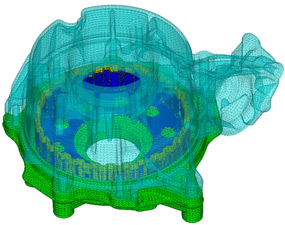

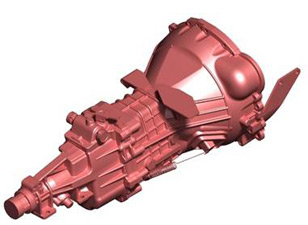

- Powertrain System Development

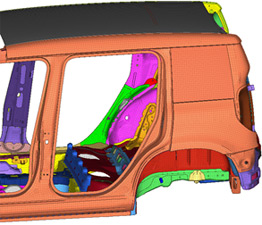

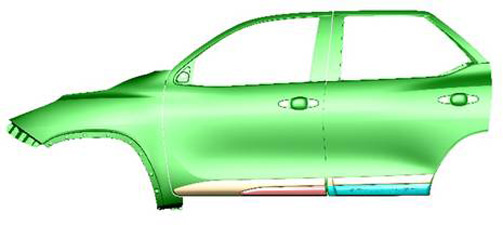

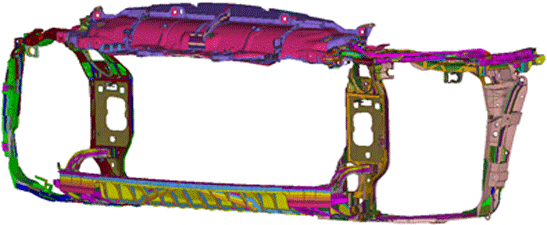

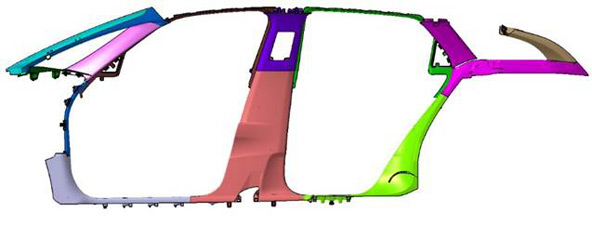

Hepatica’s BIW Design team is having wide range of experience in Body structures & its sub-system development. We are fully conversant with international standards for detail design (modeling and detailing) of the components and subsystems to integrate in the full vehicle.

- Analysis and Concept Development Support

- 2D and 3D Concept Studies

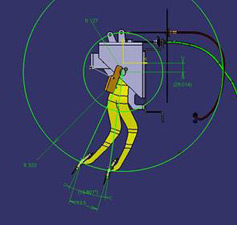

- Function Variants and Ergonomic Studies

- Styling Drafts and 3D Animations

- Drafts, Design and Detailing

- Technical Documentation

Body Structure Subsystem

- Underbody

- Body side and Quarter

- Roof

- Package Tray

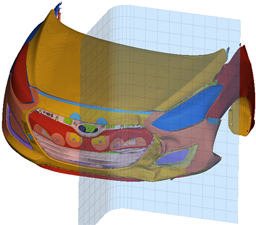

Front End Subsystem

- Front Structure

- Front Fender

- Grille Opening panel

- Deflectors and Shields

- Hood and Mounting

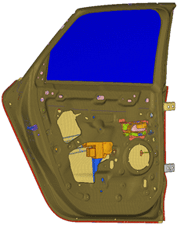

Body Closures Subsystem

- Front / Rear Doors

- Back Door / Trunk Lid

- Hood / Engine Access Door

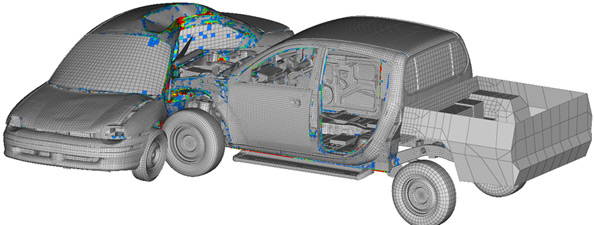

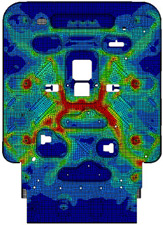

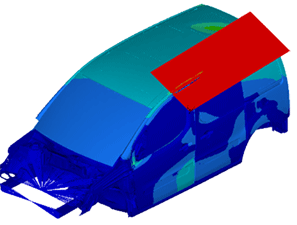

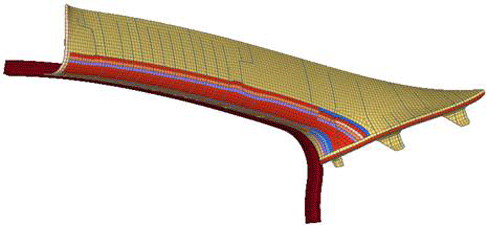

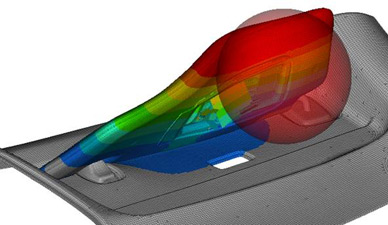

Full Vehicle Crash Simulation

- Full Frontal Impact (FMVSS 208, NCAP)

- Offset Deformable Barrier Impact (IIHS, ECE 94)

- Side Impact (FMVSS 214, SINCAP, ECE 95), Side Pole

- Rear Impact (FMVSS 301, ECE 32)

- Roof Crush (FMVSS 216)

- Compatibility of Vehicles

Durability

- Bending and Torsional Stiffness

- Sheet Metal Stress Prediction

- Joint Stiffness

NVH

- Trimmed BIW

- Normal Mode

- Frequency Response

- Point Mobility

Bumper System

- Danner/Thatcham

- Low Velocity Impacts

- IIHS Front and Rear

- FMVSS 581 / CMVSS 215

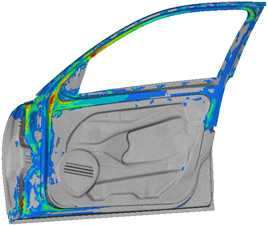

Pedestrian Impact Door Intrusion/Slam Closures

- Door Crush – FMVSS 214

- Door Slam

- Impact Beam Bench Test

- Door Dent and Ding

- Door Sag Set

- Static Overcheck

- Upper Frame Deflection

- Belt Squeeze

- Mirror Vibration

- Normal Modes and Frequency Response

- Seal Load Compensation

- Lateral Stiffness at Latch & Cowl

- Longitudinal Stiffness

- Torsional Stiffness

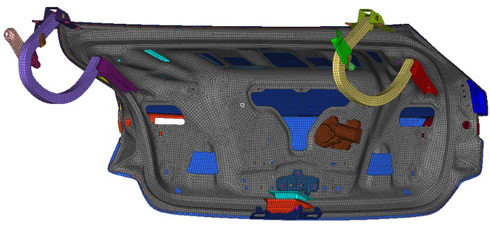

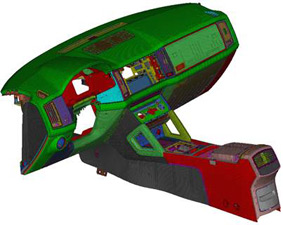

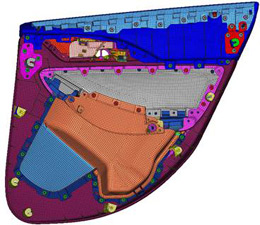

Hepatica team has broad expertise in vehicle interiors Design & Development Techniques and we are fully conversant with the methodologies of different OEM’s and tier 1 suppliers for supporting their product development from component level to subsystem level.

Interior Trim subsystem Development

- Cockpit module

- Instrument panel & Clusters

- Pillar trims (A,B,C,D)

- Cowl trim

- Roof trim

- Door panel and assemblies

- Door trim and appliques

- Front /Rear seat trims

- Seat foams (cushion foam, back foam, etc)

- Front seat springs,frame,tracks and mechanisms

- Airbag covers

Services

- Layout and packaging

- Supporting seat structure Developments.

- Class A surface development for foams from STO or curves

- Product modifications

- Design Improvements

- Manufacturing feasibility

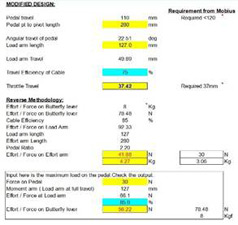

- Mechanism Designs

- 2D Drafting and Detailing

- Benchmarking

Plastic Trim Development Support :

- Aesthetic Class “A” surface or the Curves defining the required Surface.

- Recliner Environment and its behavior during its function.

- Check for the Draft Clearance of the given Class “A”Surface.

B-side attachment features Development

- Crush Fit for Recliner Knobs, Height Adjuster Knobs.

- For the Side Shield we provided attachment features like Clip Tower and Christmas tree attachments etc.

- Ribs to impart more strength to the Shields.

- Attachment for the Back Panel.

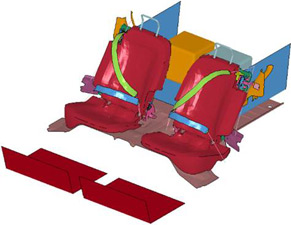

Seat Systems

- Complete Domain Knowledge: Design Support for various Type of Seats- Driver, Passenger, 2/4/6/8 Way, Captain, Bench, 2nd and 3rd Split Row, Folding, Stow-away, Manual, Power

- Seat Belt Anchorage Tests (FMVSS 207-210/ ECE14 )

- Child Restraint Anchorage (FMVSS 225/ ECE44 )

- Front and Rear Impact with Dummies (FMVSS 208/ ECE14/ECE94)

- Luggage Retention (ECE17)

- Head Restraint Strength (FMVSS 202a/ ECE25)

- Head Impact Energy Dissipation (FMVSS 201/ ECE17)

- Rearward/Forward Load Strength

- Back Torsional Rigidity, Load Floor Analysis

- Recliner, Arm Rest, Latch- Strength, Capacity

- Complex Durability Test- Low Cycle Fatigue

- Modal Analysis- Design Sensitivity Analysis

- Forming Analysis- High Strength Steel

- Bolt Load and Failure Predictions, Test Correlation

- Dyna, Abaqus, OptiStruct, Nastran, MADYMO

- Design Evaluation, Recommendation, Optimization, Validation

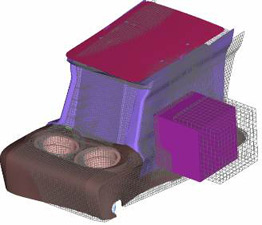

Interior Trims

- Knee Bolster on DashBoard

- Sled Test

- Front and Side Impact

- Wheel Torso Impact

- Drop Tower Test

- Head Impact (FMVSS 201)

- Pillar Trims, Headliner, Console

- Steel, Magnesium, All-Plastic Beams

- NVH with and without Body

- Random Vibration- PSD Input

- Optimization

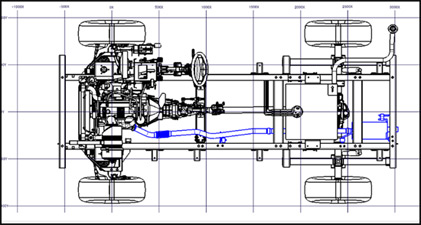

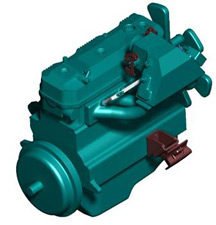

We are having wide range of experience in Powertrain and under bonnet vehicle packaging and Chassis sub- systems and we are fully conversant with the product design of individual components of the subsystems.

- Engine Subsystems and mountings

- Transmission Subsystem and mounting

- Clutch System

- Engine Cooling Subsystem

- Air charging subsystem

- Exhaust subsystem

- Suspension subsystem

- Drive line subsystem

- Brake system

- Suspension subsystem

- Fuel Subsystem

PowerTrain – CAE

- Durability Analysis

- Thermal Analysis

- Drive-line Analysis

- Gear-train Analysis

- Engine Mount Stiffness and Location

- Design of Composite Transmission Cover

- Sealing Analysis for Engine Gaskets

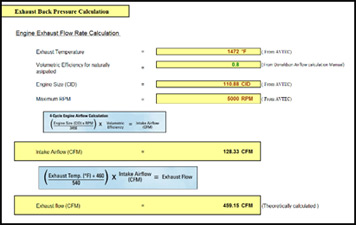

- Design Optimization of Exhaust Systems and Manifolds

- Head/Block/Gasket Thermal Analysis

- Head/Block/Gasket Local Stress Analysis

- Head/Block/Gasket Global Structural Analysis

- Head/Block/Gasket Bore Distortion Analysis

- Oil Pan Structure Analysis

- Water Pump Structure Analysis

- Balance Shaft Bending Deflection and Shaft Stress

- Flexplate Stress Analysis

- Balance Shaft Bulkhead Local Stress Analysis

- Transmission and Transfer case – Bearing Loads, Sealing

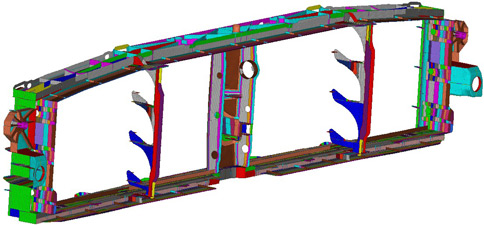

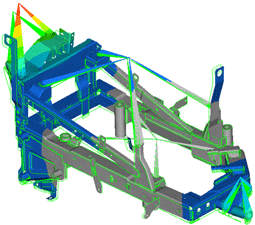

Chassis and Cradle Frame-CAE

- Under Road Load from ADAMS

- Braking, Cornering, Jounce, etc.

- Inertia Relief Analysis

- Fatigue Predictions

- Weld and Weight Optimization

Suspension Components-CAE

- Knuckle, Control Arms, etc.

- Hex and Tet Models

- Multiple Load Cases

- Wheel- Durability and Impact

- Weight Optimization

- Thermal Expansion for Clearance Check

- Column Collapse